A team of scientists from Wrocław University of Science and Technology has joined an international consortium that does research on new stealth technology materials for warships, the Wrocław university representatives report.

The project, in which researchers from the Faculty of Mechanical Engineering of the Wrocław University of Science and Technology are involved, is called ADMIRABLE, and its budget is 10 million euros. It is being carried out by a consortium consisting of shipbuilding companies and research centres. The project is financed by the European Defence Fund.

The consortium aims to develop a new material for the construction of stealth military ships (a name defining methods, strategies and technologies for camouflaging military and strategic objects). Objects made using these technologies are characterized by lower detectability, for example by radars.

'In our project, we intend to jointly develop a new composite-based material that will not only provide effective protection against detection, but will also be more efficient and provide at least the same or higher ballistic resistance than steel-based materials', emphasises Professor Tomasz Kurzynowski, the grant manager at the Wrocław University of Science and Technology, quoted in the university's press release.

He adds that by using advanced manufacturing technologies, including additive manufacturing and composite materials, the researchers from the Wrocław team intend to reduce the weight of the stealth material to about 160 kg per square meter, i.e. by about 10 percent compared to the currently used materials.

Due to reducing the weight of the materials used to build the ships, they will be able to reach higher speeds and consume less energy.

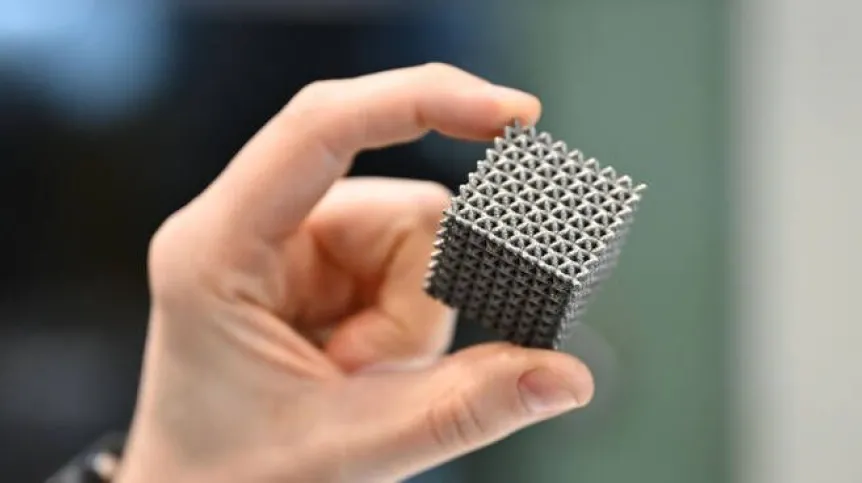

The new material is to be created by combining several production processes. 'The composite material will consist of various raw materials, including metals or polymers, with different microstructural geometries for each layer, and different mechanical, electrical and chemical properties. Currently, no manufacturing technology would be able to combine their production together. Therefore, as part of our cooperation, we will also strive to develop a combined production process of this composite metamaterial, as we call it in our documentation', explains Wojciech Stopyra, PhD, leader of the project's additive manufacturing team.

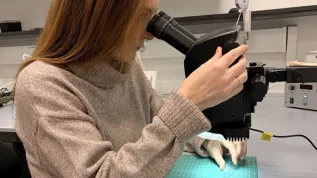

The Wrocław researchers will develop a layer of this metamaterial. It will be created using additive technologies (3D printing) from polymers, metal alloys and ceramics.

'The structure of this layer is called +sandwich+. On the outside, it will be covered with a high hardness ceramic coating, the task of which will be to change the trajectory of the projectile hitting this material. Inside, there will be metal alloys in the form of lattices, i.e. an openwork material, the task of which will be to absorb the energy of the projectile's impact, i.e. to stop it', Stopyra explains.

The last coating will consist of polymers, and its task will be to 'intercept' fragments of the projectile. 'You can imagine this by recalling how a car window shatters. It does not break into tiny pieces, because it has a layer of foil inside that holds these small fragments together', Kurzynowski adds.

The metamaterial that the Wrocław scientists are working on will find application not only in the construction of military ships, but also in other structures for military purposes.

Work on the ADMIRABLE project will take three years. The consortium members are centres from Spain, Italy, Germany, Luxembourg, Cyprus and Poland. The project is managed by the Spanish shipbuilding company Navantia. The Italian shipbuilding company Fincantieri, the largest in Europe and fourth in the world, also participates in the consortium. (PAP)

PAP - Science in Poland

pdo/ bar/