Materials as lightweight and resistant as plastic, yet fully biodegradable and... created from waste? Scientists from the Institute of Physical Chemistry PAS are working on an ecological, waste-free and economical method of obtaining organic monomers.

"Today`s plastics, made from petroleum, contain phthalates and other plasticizers - a `soup` of organic and inorganic compounds, which no bacteria or fungus can break down on their own. That is why they remain in forests and seas for so long" - says Prof. Juan Carlos Colmenares from the Institute of Physical Chemistry PAS. He announces:" We want to replace PET with something that would break down over several months, a few years at most".

Prof. Colmenares` team is working on a material that is as light, as resistant as plastic, and fully biodegradable. The researchers have developed a new method for producing DFF (2,5-diformyl furfural). The results of their research have been published in the journal Applied Catalysis B: Environmental (https://doi.org/10.1016/j.apcatb.2019.117803). The Institute of Physical Chemistry PAS informed about the project it in a press release sent to PAP.

Until now, relatively high temperatures (100-150 degrees C) and complex technology were needed to produce DFF. As a result, this material - although ecological - could not compete with petroleum-based products.

Meanwhile, DFF is a dream compound: despite the high cost of its production, it has found application in many industries. It is useful not only in the production of environmentally friendly plastic, but also in the production of medicines, cosmetics, fragrances, chemicals and fuels.

The scientist quoted in the Institute of Physical Chemistry PAS release explains that DFF-based polymers have already been tested. "They break down into sugar-like monomers. And sugars are a tasty bite for many microorganisms. Even if a bottle made of such plastic is thrown away in a forest, it will decompose much faster than conventional polymers - in a few years at most" - he assures.

It is not the product itself (DFF) that is a novelty, but the method of obtaining it. Researchers have obtained the compound from HMF (hydroxymethylfurfural) - a material produced on an industrial scale from products such as cellulose, lignin or inulin - paper industry waste.

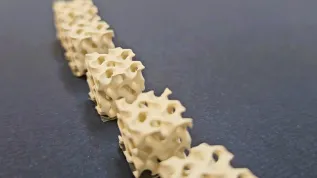

To transform HMF into DFF with the method developed by Prof. Colmenares` team, a photoreactor can built by researchers is needed. The reaction occurs under the influence of light (for now from LED lamps, ultimately solar energy will be used).

The heart of the reaction is the catalyst: manganese dioxide nanowires. "They are long and very, very thin, and their structure increases the absorption of light. (...) Virtually all HMF is converted into DFF" - the professor says.

The scientist assures that the method of producing DFF from HMF is waste-free. He explains that oxygen from air is enough to obtain pure monomer needed for the production of linear polymers and, for example... bottles. And nanowires can be reused as a photocatalyst, because DFF does not destroy them. The reaction can take place at room temperature and atmospheric pressure.

Won`t such quickly decomposing plastic break down too quickly? Before, for example, we can drink the juice from the bottle made of it? "No!" - the professor laughs. "In practice, it takes several years to decompose it". He assures that the polymer is harmless to humans and even enzymes and intestinal bacteria present in the human body can break it down.

PAP - Science in Poland

lt/ agt/ kap/

tr. RL