Thin uranium targets play a key role in the production process of molybdenum-99, a valuable radiopharmaceutical. The European patent recently granted to scientists from the National Centre for Nuclear Research in Świerk can optimise this production thanks to targets made using 3D printing.

Modern methods of imaging the structure and functions of the human body (needed, for example, in the diagnosis of cancer) largely depend on radiopharmaceuticals - active substances containing appropriately selected radioactive isotopes. Once the radiopharmaceutical is introduced into the patient's body, its flow rates and accumulation sites can be monitored by recording the photons emitted by the nuclei of the decaying radioisotope.

Today, 80% of diagnostic procedures using radiopharmaceuticals require the use of molybdenum-99. 'In the future, the production efficiency of this valuable radioisotope can be increased, also thanks to uranium targets prepared by spatial printing. The European patent for such a solution has just landed in the hands of scientists from the National Centre for Nuclear Research in Świerk, Poland', representatives of the institute report in a release sent to PAP.

'The global demand for molybdenum-99 is huge. It is a radioisotope that is usually produced in research nuclear reactors, i.e. in devices with limited production capacity. That is why it is so important to constantly improve the methods of its production', says co-inventor of the patent Professor Paweł Sobkowicz from the National Centre for Nuclear Research, quoted in the release.

The half-life of molyb-denum-99 is 67 hours. This time ensures the possibility of transport of the radioisotope from the place of production to the hospital.

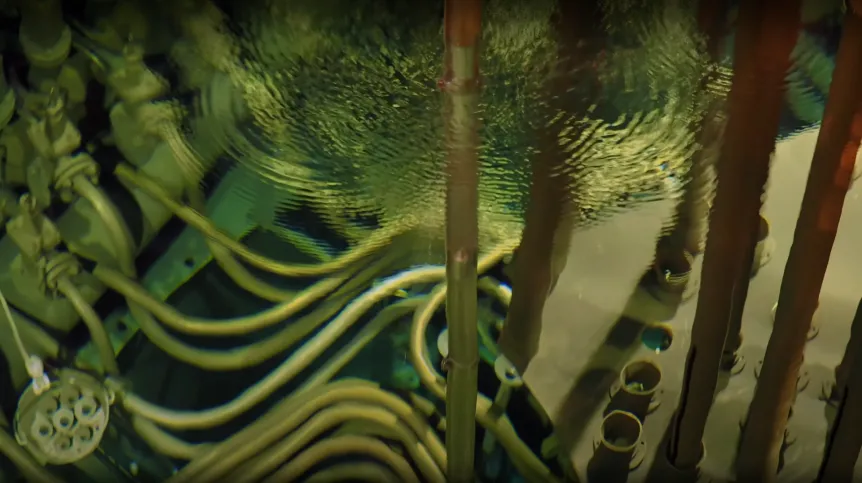

'Molybdenum-99 is most commonly produced by irradiating small targets containing low-enriched uranium-235 with neutrons', says Maciej Lipka, one of the co-authors of the patent. 'Reactor neutrons have a limited ability to penetrate the target material. To ensure that as many uranium-235 nuclei as possible are converted to molybdenum-99, the targets are typically prepared as thin plates from a dispersion of uranium or its oxide or silicide in aluminium. The plate production process does not leave much room for optimisation. Therefore, we proposed a different way to prepare uranium targets: spatial printing by laser powder sintering'.

Laser sintering of metal powders is a type of 3D printing that involves using a laser of appropriate power to selectively melt a thin layer of powder, previously evenly distributed inside the container on the working platform. After the first layer is fixed, the platform is lowered slightly, the next layer of powder is applied and the whole cycle can be repeated as required.

'3D printing techniques have been known for a long time, but so far they have not been used to produce uranium targets for neutron irradiation in reactors. However, we believe that this way of producing targets can have a number of advantages”, says Professor Paweł Sobkowicz.

Nuclear reactions take place in a target exposed to neutrons. Their by-product is heat. According to the representatives of the institute, the use of 3D printing allows to optimise the shape of the targets so that the heat is more effectively dissipated. The targets themselves would therefore heat up less, and that would increase the uranium-235 content in them. As a result, more molybdenum-99 per exposure could be produced.

'When firing neutrons, not only molybdenum-99 is formed in a uranium target, but also many other isotopes. After removal from the reactor, each target must therefore be subjected to appropriate chemical treatment, which serves to isolate the molybdenum. Meanwhile, with the help of spatial printing, it is possible to prepare, for example, openwork targets with very large active surface areas, interacting more effectively with chemical solvents', says Lipka.

According to the representatives of the institute, probably the most promising aspect of the patent relates to the potential to increase the processing efficiency of the uranium-235 itself. In each irradiated target, some of the nuclei of this isotope do not undergo nuclear transformations. The shapes of the printed targets can therefore be designed to increase the amount of uranium recovered. Once extracted, it could be used to build more targets.

'Currently, more than 10% of the world's demand for molybdenum-99 is covered by the Polish research nuclear reactor Maria, located in Świerk near Warsaw. NCBJ also houses the POLATOM Radioisotope Centre, a manufacturer of technetium generators that are exported to over 70 countries', the representatives of the institute report.

PAP - Science in Poland

lt/ agt/

tr. RL