Scientists from the Łukasiewicz – Industrial Chemistry Institute in Warsaw have developed a new class of hydrogels made from natural polymers, including starch, that can self-repair structural damage within hours.

The new hydrogels are a response to growing concerns about the environmental impact of synthetic polymer-based materials, according to Dr. Katarzyna Łęczycka-Wilk from the Biomaterials Section of the institute.

“Hydrogels made of synthetic polymers have been used for years in many industries—from medicine to the cosmetics industry—thanks to their flexibility and excellent absorption properties,” Dr. Łęczycka-Wilk said. “Unfortunately, their widespread use is associated with environmental problems and high environmental costs. Most synthetic polymers do not decompose naturally, which leads to the accumulation of waste. In addition, their production is often associated with the emission of toxic substances and high consumption of non-renewable raw materials, such as crude oil.”

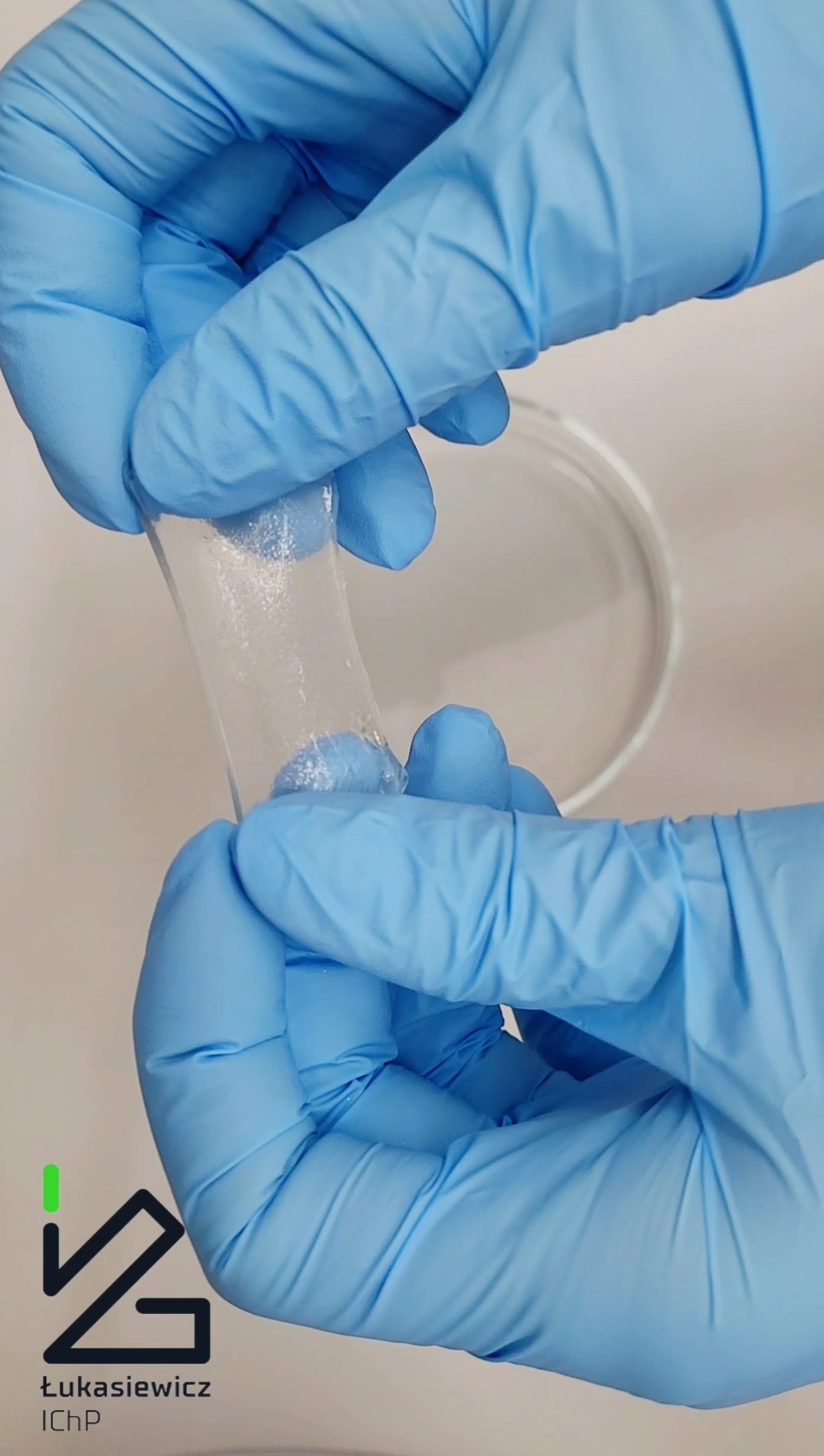

In contrast, the newly developed hydrogels are composed of renewable plant-based ingredients, primarily starch and glucomannan, making them fully biodegradable. Dr. Łęczycka-Wilk explained, “The hydrogels themselves are three-dimensional polymer networks, capable of absorbing and retaining significant amounts of water and biological fluids without losing their structural integrity.”

The new materials are capable of absorbing up to 35 times their own weight in water. “Alkaline conditions additionally increase this capability, while the addition of citric acid reduces the degree of swelling, while strengthening the structure of the material, acting as a cross-linking agent,” she said.

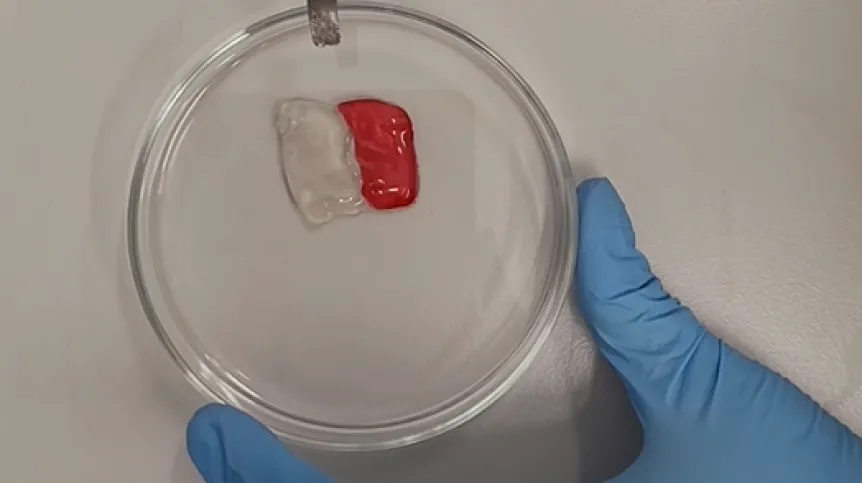

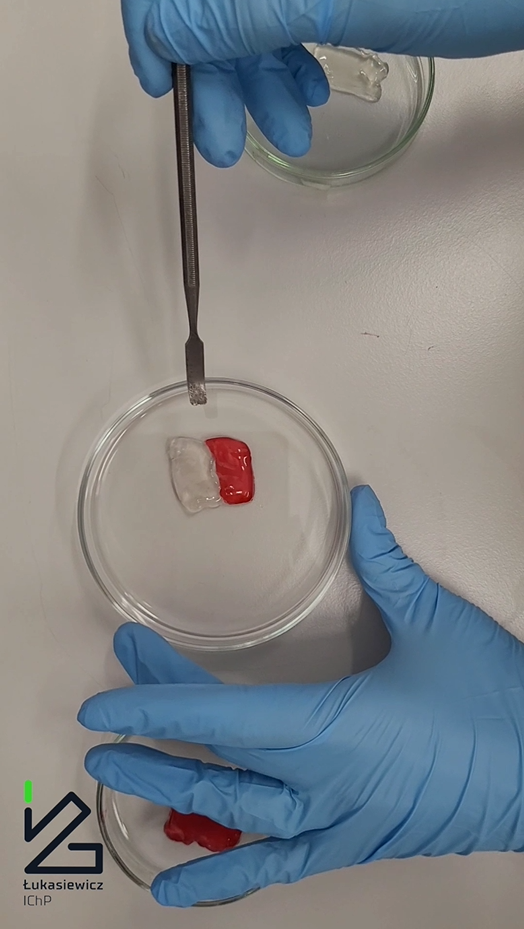

One of the most significant features of the new hydrogels is their ability to self-heal. “Moreover, our hydrogels have a unique self-repair capability,” Dr. Łęczycka-Wilk noted. “They can rebuild their structure in just a few hours after damage occurs, making them exceptionally durable and reliable in medical applications.”

Thanks to bioactive additives, the hydrogels also offer hygienising and antioxidant properties. “The highest antioxidant activity was recorded in hydrogels with the addition of hydrophobic DES (deep eutectic solvents) based on menthol, thymol, and vanillin,” she reported. “These materials also exhibit high thermal stability—at a temperature of 150 degrees Celsius, the mass of the hydrogel is reduced by only 5 percent.”

Potential applications for the new hydrogels are wide-ranging. “They can be used to support wound healing, as intelligent dressings which automatically rebuild their integrity after damage, providing continuous protection and an optimal microenvironment for tissue regeneration,” Dr. Łęczycka-Wilk said. “They can also serve as biocompatible implants, controlled-release drug carriers, or materials for tissue engineering that support regenerative processes by imitating the properties of the extracellular matrix and stimulating cell proliferation.”

Beyond medical applications, the development aligns with global efforts to reduce environmental impact and promote circular economy principles. “Hydrogels based on natural polymers are biodegradable, biocompatible, and fit into the assumptions of the circular economy,” Dr. Łęczycka-Wilk said. “Their production allows to reduce the consumption of non-renewable raw materials and the emission of harmful substances, while offering a new quality in wound treatment, cosmetics, and other biomedical applications.”

Currently, the team is advancing to the next phase of development. “Intensive laboratory work is currently underway, in which the physicochemical and functional properties of the hydrogel are being tested,” she confirmed. “We are working on creating a prototype that may find applications in future medical dressings.”(PAP)

PAP - Science in Poland

akp/ zan/