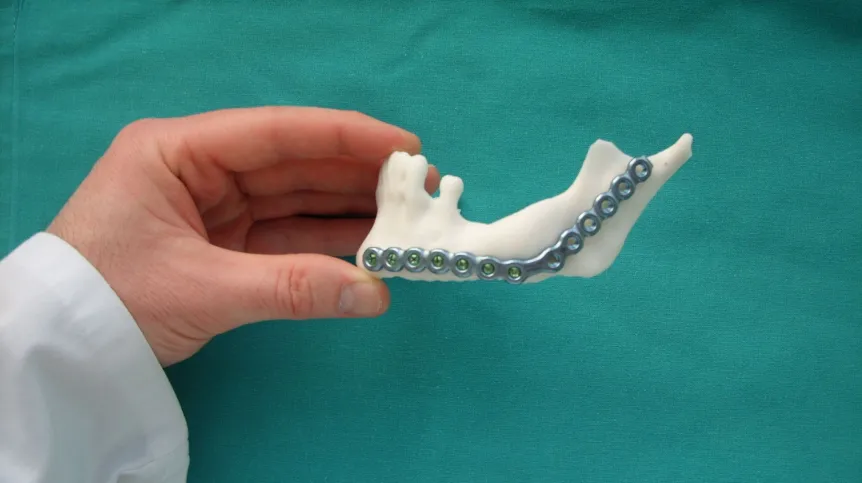

3D printed mandible model has been developed at Rzeszów University of Technology. Its use significantly shortens the time of surgical implantation and minimizes the risk of intraoperative complications.

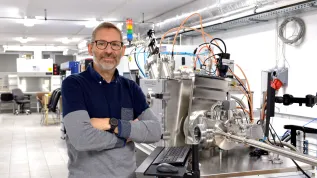

Surgeon can use the printed medical model of the mandible to adjust the implant to the particular patient even before the procedure. "It is tailor-made" - says the model creator, Dr. Paweł Turek from Rzeszów University of Technology. His research and the process of mandible model development were the subject of his doctoral dissertation "Methodology of designing and manufacturing medical models of the mandible".

Dr Turek said in an interview with PAP that during the research he consulted specialists from the Oral and Maxillofacial Surgery Clinic in Rzeszów, modified and improved the developed solutions, selected the appropriate parameters until achieving the finished medical model of the mandible.

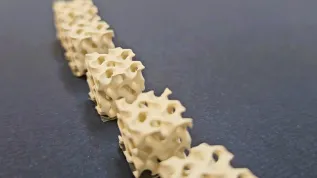

During his research he was able to develop a procedure that enables the reconstruction of the mandible geometry before the occurrence of damage, and the assessment of the mandible damage degree. This means that the printed model is almost identical to the "original" anatomical mandible of a particular patient.

"3D models of bone structures allow for better preparation of the surgeon for surgery and increased precision, which leads to a significant reduction of surgery time and minimizes intraoperative complications. Moreover, the use of such a model contributes to reducing blood loss during surgery" - said Dr. Turek.

The printed model, which is individual for each patient, allows the surgeon to adapt the implant for a particular person. This happens before the surgery. When using a traditional procedure, the surgeon adapts, "measures" the implant during the procedure, which significantly exptends the operation time.

In addition, after the procedure with the use of the printed model the patient\'s convalescence period is shorter and - depending on the degree of the mandibular damage - the patient may return to normal functioning.

Another advantage of 3D model is that the patient, having seen it before the procedure, can more easily imagine the surgeon\'s actions when the surgeon explains the course of the entire process.

The author of the mandible model made with the 3D printing technique noted, however, that designing and making an accurate medical model for the needs of a surgical procedure was not a simple task. The problem is that the mandible is a bone tissue with a very complex geometry.

"Appropriate knowledge and skills in the field of medicine and technical sciences are needed to fully use the tools to carry out such a task" - emphasised the scientist. He added that this was the reason for the need for close cooperation and consultation with specialists.

He explained that he chose the mandible because it was the only movable craniofacial bone subjected to multidirectional dynamic loads during biting or chewing.

Dr. Turek\'s research process was co-financed as part of the activities of the Innovation Incubator "Methodology of designing and manufacturing high-quality facial models with high accuracy".

The scientist intends to patent the model of the mandible he has developed.

He is currently involved in the research on the cranial vault (the goal is to improve the process of its segmentation and reconstruction) and accurate preparation of small and complex objects, such as the cores and crowns of teeth.

"Reconstructive engineering is used today in many fields, for example in medicine, where it can be used in the process of restoring the geometry of internal anatomical structures and the production of implants" - noted Dr. Turek.

He also conducts research within the framework of the Cluster "Technology in Medicine" - TECHNOMED, where he makes surgical models and templates using 3D printing techniques, including models of pelvis, femur, which significantly facilitate planning and conducting surgery.

He assured that as part of the cluster\'s activity, he plans to extend his research to include other bone structures. "Their selection will depend on the demand" - he noted. (PAP)

PAP - Science in Poland

author: Agnieszka Pipała

api/ zan/ kap/

tr. RL