Scientists from the Institute of Electronic Materials Technology in Warsaw are testing the world`s first high-temperature magnetic field sensor made of graphene. This technology can be used in the production of electric cars and industrial equipment.

Graphene - a carbon lattice with the appearance of a honeycomb and the thickness of one atom - is already used in such products as touch screens or photovoltaic cells.

Yet another application of this material has been found by scientists from the Institute of Electronic Materials Technology in Warsaw. Since the beginning of this year, they have been working on a magnetic field sensor made of graphene, according to the institute`s press release sent to PAP. This sensor will use a patented technology of graphene deposition on silicon carbide. According to the authors, the solution is expected to work in extreme temperatures.

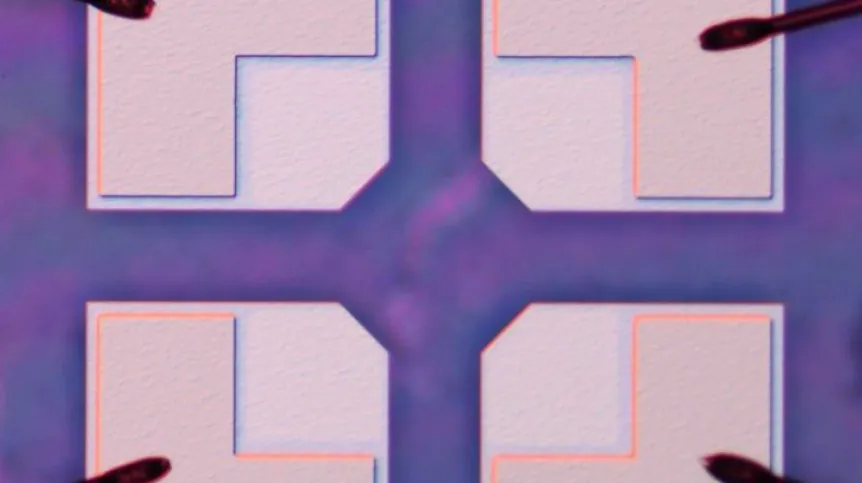

The sensor`s operation is based on the so-called Hall effect. To detect the presence of magnetic field, electricity runs through graphene. The stronger the field, the higher the voltage in the detector. Devices that detect magnetic field this way are called hallotrons.

"There are sensors available on the market that use the same effect, but they are built with silicon, gallium arsenide, indium arsenide or indium antimonium, which are semiconductors. We use graphene deposited on silicon carbide" - explains Dr. Tymoteusz Ciuk from the Institute of Electronic Materials Technology. "Graphene is much more temperature resistant. This sensor can be cooled in liquid nitrogen, that`s minus 200 degrees Celsius, it can also be heated up to 500 degrees. And it will still work" - he emphasises.

Specialists from the Institute of Electronic Materials Technology see possible applications of the sensor in industrial automation, metrology, mining, production of engines for electric cars and production of equipment for the army.

"But we do not really know the full potential our project. Our knowledge about the use of the detector increases from month to month. We might still find applications for the sensor that we do not know about today" - says Dr. Ciuk.

Now the Institute of Electronic Materials Technology is looking for companies with research and development facilities that would like to test the sensor and use it in their products.

The project financed by the National Centre for Research and Development will continue until the end of 2020.

PAP - Science in Poland

kflo/ agt/ kap/

tr. RL