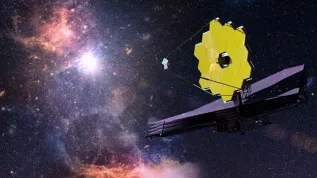

The mechanisms developed by Astronika worked correctly during the flight of the JUICE spacecraft, which is heading towards Jupiter.

Polish space company Astronika supplied two of the six mechanisms that were to be deployed in space on board the JUICE spacecraft launched by the European Space Agency (ESA).

'I am proud of everyone involved in the preparation of +our+ instruments. Today's success has shown that we have refined everything to the last detail. Each successful space mission is the result of many years of cooperation between dozens of entities, hundreds of scientists, engineers and managers. It was the same this time. As a result of our work, several new technologies were developed and a patent obtained. The development and provision of appropriate components required close, long-term cooperation of a number of Polish subcontractors,’ says Łukasz Wiśniewski from Astronika.

Poland contributed both industrially and scientifically to the project. This applies particularly to Astronika, and in the scientific area to the Space Research Centre of the Polish Academy of Sciences.

The work of Polish constructors was related to the LP-PWI and RWI instruments of the JUICE spacecraft. All components must be resistant to extreme environmental conditions, for example temperatures of plus 250 degrees Celsius during the Venus flyby and minus 230 degrees Celsius near Jupiter. In addition, they must be durable, but very light, and deploy to large sizes: RWI was 26 cm long during launch, and about 2.5 meters after it was deployed in space, while LP-PWI positions the measuring sensors at a distance of three meters from the spacecraft.

A number of entities from Poland and abroad participated in the preparation of the experiment as part of the JUICE mission. Commissioned by Astronika, a number of Polish institutes and companies developed new technologies or performed expert tests. The Warsaw University of Technology prepared specialized coatings and surface treatments. Koszalin University of Technology made specialized DLC coatings for RWI (Radio Wave Instrument) antenna tubes. The Institute of Electron Technology sputtered resistive layers onto the ceramic resistor of the Langmuir probe. The Institute of Aviation conducted vibration tests of the RWI antenna.

Among industrial entities, services were commissioned from: ELPOD - development and production of thermal resistors, Gutronic - delivery of patented tubes for RWI antennas, Wareluk S.C. - production of thin-walled, titanium alloy details of the Langmuir probe sensor, Coating S.C. - development of a ceramic base for the Langmuir probe sensor resistor, Smart Metrology - non-contact measurement of the geometry of the assembled LP-PWI booms to verify the assembly accuracy, Towes - supply of springs for the LP-PWI hold and release mechanism, ARP S.A. - co-financing of software for engineering design and analysis.

The project leader was the Institute of Plasma Physics in Uppsala, Sweden. In Poland, the beginning took place at the Space Research Centre of the Polish Academy of Sciences, where prototypes of devices were created in 2015-2016. Subsequently, the European Space Agency (ESA) commissioned Astronica to carry out further work: design, production, integration and testing of a number of models at various stages. Over the course of six years, the company built 10 models of LP-PWI booms and 10 models of RWI antennas. Individual components for these devices were also made as part of an international consortium in Japan, Sweden and Germany.

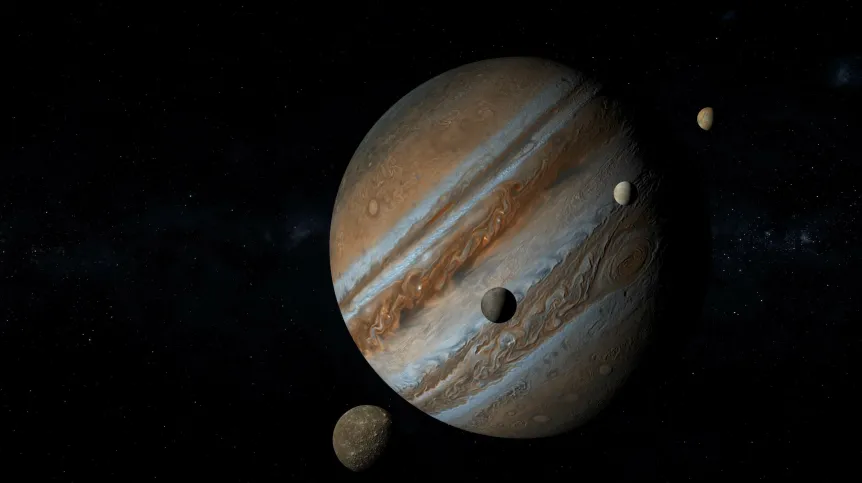

The JUICE space mission objective is to study Jupiter and its moons, in particular Ganymede, Callisto and Europa. The spacecraft was launched on April 14 this year. It will reach Jupiter in 2031.

In total, 18 institutions, 23 countries, 83 companies are involved in the ESA project, 116 industrial contracts have been signed, over 2,000 people have participated in the work, and the cost of the mission is approximately EUR 1.6 billion. (PAP)

cza/ agt/ kap/

tr. RL