The development of next generation implantation biomaterials is the goal of research conducted by scientists from Poland and Austria. As a result, surgical implants will be more durable and of better quality, and this will translate into less frequent removal or revision.

The project is headed by Dr. Agnieszka Tomala from the Cracow University of Technology and Professor Carsten Gachot from the Vienna University of Technology. The University of Lodz is also a partner. The Polish teams' research is financed by the Polish National Science Centre as part of the OPUS 24+ LAP call.

'Our research addresses the challenges of an ageing population and the observed increase in the use of orthopaedic implants. Today's implants are designed for the greatest possible durability, but in reality they are imperfect,’ physicist Dr. Agnieszka Tomala tells PAP.

The scientist says that cyclical loads and friction lead to abrasion and the formation of wear particles that cause inflammation, and consequently to the failure of the entire implant and the need for surgery to remove or revise (replace) it. 'Therefore, it is necessary to osseointegrate the composite biomaterial with the bone, which will prevent loosening of the implant, and thus improve its durability,’ she says.

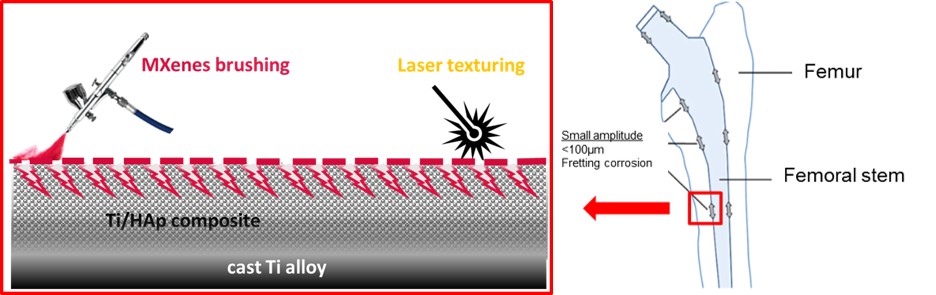

The objective of the project is to develop an innovative composite biomaterial of high quality and durability. This material consists of titanium (Ti), hydroxyapatite (HAp) and the innovative two-dimensional nanomaterial MXene. 'MXene has a layered arrangement of two-dimensional structures, creating a flake morphology that slides easily relative to each other. MXenes usually consist of titanium and carbon, which already have proven, excellent properties in many technical and medical applications,’ Tomala says.

In addition, scientists will use an innovative technique in their research work. 'Laser radiation will be used to create orderly arranged small pockets on the material surface. This laser structuring opens deep pores in the Ti/HAp/MXene composites, which will further enhance the transport and growth of osteogenic cells in the implant area. In addition, the laser pockets can serve as reservoirs for lubricating fluids to reduce friction and wear on the involved surfaces. In this particular solution, the lubricant that improves the tribological characteristics will be Mxene,’ Tomala says.

The newly-developed biomaterials will then be subjected to in-vitro biocompatibility assessment: comprehensive microbiological, pro-inflammatory, pro-regenerative and morphological tests using cell culture techniques.

The project is basic research. Before potential implementation, and before the biomaterial can be used for treatment, it would have to undergo a lot of testing, including the assessment of safety and in vivo bioactivity of the used materials, exclusion of potential genotoxic/carcinogenic effects, exclusion of interactions with blood and skin irritation/sensitisation as well as qualitative and quantitative characteristics of the degradation products of the tested materials.

The project 'Next Generation Bioactive Laser Textured Ti/Hap/Mxene Biomaterials' is financed by the Polish National Science Centre under the OPUS 24+ LAP call. Research tasks carried out by Polish teams will be financed by the National Science Centre with the amount of over PLN 1.7 million, while the cost of work of Austrian teams will be covered by the Austrian Science Fund (FWF).

The partners of the project are: the Faculty of Materials Science and Physics of the Cracow University of Technology, the Faculty of Biology and Environmental Protection of the University of Lodz and the Faculty of Mechanical Engineering of the Vienna University of Technology.

PAP - Science in Poland, Agnieszka Kliks-Pudlik

akp/ agt/ kap/

tr. RL