Polish researchers have developed luminescent nanomaterials that change the colour of emitted light with local pressure. Thanks to this, it will be possible to remotely and continuously monitor the distribution of stresses in structures and diagnose whether anything in them is starting to fail.

In devices such as engines, furnaces, technical structures, in machine parts, buildings or bridges - any change in the stress in the material may indicate that the part is damaged, weakened, or is failing. So if the pressure or stress increases in a given place, it may mean that soon the given part will break, crack, leak or even explode. And such damage may not only be difficult to repair, it may also pose a threat to the safety of people in the vicinity of the structure. So it would be good to have information in advance that a part is starting to fail.

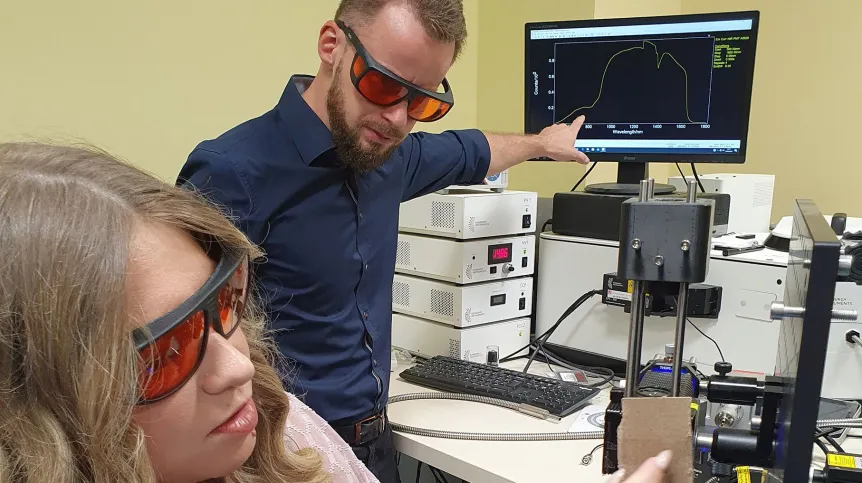

That is why Professor Łukasz Marciniak and doctoral candidate Maja Szymczak from the Institute of Low Temperature and Structural Research of the Polish Academy of Sciences developed a new method of measuring pressure using proprietary luminescent materials.

The solution involves covering the structural element with paint or varnish that contains luminescent nanomaterials. Such paint, illuminated with the right type of light, begins to glow, and the colour (more precisely: its emission spectrum) changes with the pressure in a given place. A properly working structure will, for example, glow red when illuminated, and the place of damage in the material will glow green.

The material can also be designed so that the change can be seen even with the naked eye, but an accurate map of the pressure distribution in the structure can be obtained by taking two photos of the surface with an ordinary smartphone and comparing them using a simple photo analysis application.

'Our solution can work continuously and remotely. There is no need to connect electrical circuits or power to the tested structure. If we point a camera at a given part, we can continuously analyse the pressure distribution in the tested system without stopping the device. We find out where damage occurs in real time. This will not only reduce the cost of diagnostics, but above all enable quick diagnostics,’ Professor Łukasz Marciniak tells PAP - Science in Poland.

He explains that luminescence manometry, i.e. pressure measurement using spectral analysis of light emitted by a given material, has been known for years. 'However, if we wanted to test stresses conventionally, it would be time-consuming and cumbersome,’ he says.

As he describes, pressure readings have so far been made in specific points, so the pressure distribution over the entire tested surface could not be seen. In addition, luminescence would change not only in response to changes in pressure, but changes in temperature. And this is an additional problem when reading the pressure.

'We proposed a method that changes the measurement paradigm: a ratiometric reading - we analyse the ratio of luminescence intensity of the signals in two spectral ranges. So we photograph the object using one filter, then another, we divide both photos and obtain a map of pressure distribution', the scientist says and adds that a simple smartphone is sufficient for this.

It is something completely new. 'The intensity ratio of the two spectral ranges for the materials we have developed is not very sensitive to temperature changes. As a result, we achieve high precision and sensitivity of the reading. And the temperature in the tested object does not affect the measurement,’ the researcher adds.

Researchers have developed phosphors (chemicals that emit light when exposed to energy) that exploit the spectral shift of a wide emission band (their colour changes markedly with pressure). 'Our material has broken a world record - it has a wavelength shift of the emitted light of more than 23 nm per gigapascal'. (It can be assumed that red and yellow light differ in wavelength by about 100 nm).

In addition, nanomaterials can be specifically designed for a given application. 'Luminescence colours can be calibrated to certain pressures', the scientist says. So if constructors decide, for example, that an increase in pressure from 1 to 2 gigapascals requires attention, it will be possible to develop a paint that will respond to such a change with a distinct colour change.

'I have been dealing with luminescent thermometry for years. We were developing materials that changed emission depending on temperature. Then I realized that there was no way to analogically image pressure in two dimensions. And that would be useful in engineering. So we developed a completely new technique to read pressure and we found materials that met the assumptions. Thanks to this, a pressure distribution map will be visible in an instant,’ says Professor Marciniak.

The nanomaterials proposed by the Polish researchers are doped with chromium 3+. As pressure changes, the distances between the ions of the material also change, so does the strength of the crystal field, which affects the colour of the emission. The research results were published in the Chemical Engineering Journal. (PAP)

PAP - Science in Poland, Ludwika Tomala

lt/ bar/ kap/

tr. RL