Scientists at the University of Warsaw have developed a nanocatalyst that transforms waste glycerol and carbon dioxide into glycerol carbonate, a potentially cheaper and greener route for producing materials used in lithium-ion batteries, bioplastics, and pharmaceuticals.

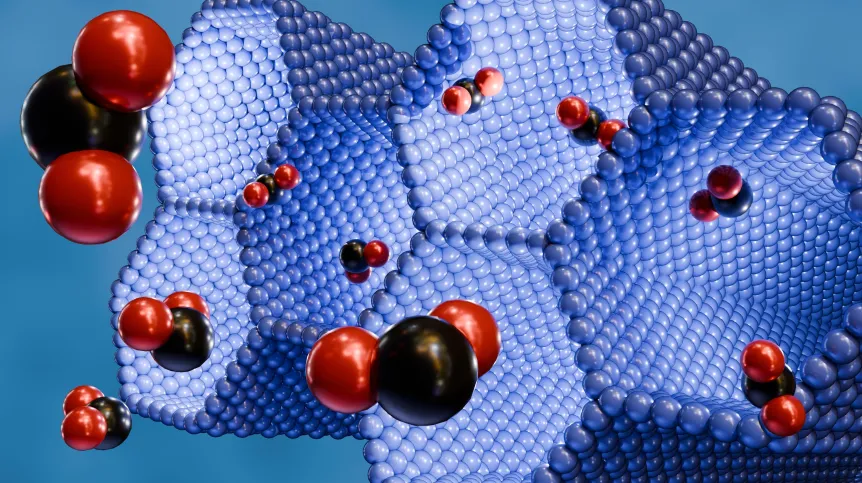

The PdCu@MOF-Ce catalyst, created by researchers from the Laboratory of Organic Nanomaterials (NanoOrgMat) and the Laboratory of Organic Functional Materials Technology at the University of Warsaw, in collaboration with the University of Lund (Sweden), combines cerium-based metal-organic frameworks (MOFs) with palladium and copper nanoclusters. The material allows carboxylation of glycerol with carbon dioxide, transforming two waste substances into a valuable chemical compound.

Michał Wójcik, PhD, co-author of the study published in the Journal of CO2 Utilization, explained in an interview with PAP that the action of the new nanocatalyst is based on MOF structures, a class of porous materials whose importance in chemistry was honoured with the Nobel Prize this year.

“MOFs (metal-organic frameworks) are materials made of metal ions connected by organic molecules, forming a 3D network of microscopic pores and channels. Gas and liquid molecules can be retained or react inside them, which makes them an ideal environment for chemical reactions,” he said.

The research team used this property of MOFs to create a material containing cerium (Ce-MOF), with nanoclusters of palladium (Pd) and copper (Cu) placed in its pores. The resulting PdCu@MOF-Ce nanocatalyst allows carboxylation of glycerol with carbon dioxide under mild conditions, converting two waste products into glycerol carbonate (GLC).

Wójcik said that carbon dioxide is a greenhouse gas, and glycerol, a by-product of biodiesel and fatty acid production, is produced in large quantities, making its disposal challenging.

“The reaction developed by our team allows us to convert both of these wastes into an industrially very useful substance,” he said. “Glycerol carbonate has a very wide range of applications: lithium-ion batteries, pharmacy, cosmetics, and the production of biodegradable plastics. In the age of intensive development of energy technologies and electromobility, its importance has significantly increased.”

He added that previous production of glycerol carbonate required high pressure, elevated temperature, and pure substrates, which made the process expensive. The new catalyst eliminates these limitations, allowing the reaction to run with less energy and without toxic reagents.

Wójcik explained that the key was to increase the reaction surface. “The larger it is, the more effective the catalytic process is, because the number of places of contact with the reactants increases. And MOFs, due to their unique, porous structure, increase this surface area many times,” he said.

Each palladium and copper atom enclosed in the pores of Ce-MOF as nanoclusters can actively participate in the reaction without aggregating into larger particles, and the material remains stable and reusable, Wójcik added.

“It is a bit like human alveoli or the folds of the small intestine. In both cases, increasing the exchange surface enables more intensive processes. It is similar in nanoparticles: their huge active surface makes chemical reactions occur much faster and more efficiently,” he said.

He said the combination of MOF with metal nanoclusters determines the unique properties of the material. “At this scale, i.e. below one nanometer, metal nanoparticles or clusters have a disproportionate number of active sites that can catalyse reactions. Thanks to this, the catalyst works more efficiently, even though it contains very small amounts of precious metal, which makes the entire process more profitable.”

The system is also scalable, allowing use beyond laboratory conditions. “The newly developed catalyst allows the reaction to be carried out under conditions of moderate pressure and temperature, which can be reproduced in standard industrial reactors. There are no stages that would limit production on a larger scale,” he said.

Wójcik added that the invention, PdCu@MOF-Ce, represents a successful combination of basic research with application potential.

The team is continuing to investigate the use of other, cheaper metals and the expansion of this approach to other CO2-based reactions, but the priority remains to further improve the process leading to glycerol carbonate.

The nanoparticles and nanoclusters of platinum-group metals used in the solution can be obtained using technology patented by the University of Warsaw.

Katarzyna Czechowicz

kap/ zan/ ktl/

tr. RL