Scientists at the Institute of Nuclear Physics of the Polish Academy of Sciences (IFJ PAN) have developed a method for coating large metal surfaces with precisely formed nanostructures, overcoming a limitation that has long hindered applications in medicine, energy, and electronics.

Until now, producing homogeneous coatings on large metal surfaces was impossible because crystalline grains disrupted the growth of nanostructures.

Researchers in Kraków say they have solved the problem, demonstrating the technique on titanium and titanium oxide.

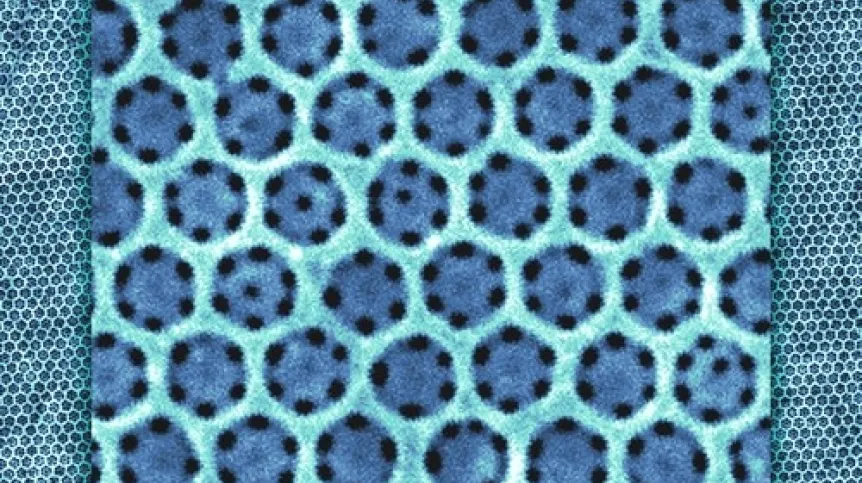

“We are unique in the world in our ability to coat large areas of titanium sheet metal, measuring tens of square centimetres, with titanium oxide nanotubes in a strictly controlled manner. The method we propose is the result of combining two unconventional techniques for nanostructuring material surfaces: nanoparticle lithography and electrochemical anodization,” said Juliusz Chojenka, PhD, the first author of the paper published in Acta Materialia

According to IFJ PAN, the process is simple, fast, inexpensive, and easily scalable for technological use. Potential applications include medical implants, photovoltaic cells, chemical detectors, and memristors.

Nanoparticle lithography is used in the preparatory stage, where spherical polystyrene nanoparticles are deposited in a uniform monolayer on a titanium plate. Plasma treatment shrinks the spheres while keeping them in place.

A thin titanium layer is then deposited, and the nanoparticles are removed, leaving a hexagonal grid of pits known as antidots.

The sample is subjected to anodization, an electrochemical process that forms ordered nanostructures. “By skilfully selecting the composition of the electrolyte in which anodisation takes place, and by controlling the applied voltage, temperature and time, we are able to form a dense coating of titanium oxide nanotubes, arranged in accordance with the original antidot pattern and with a predetermined length, which in the case described in our article is 15 micrometres,” said Michał Krupiński, PhD, quoted in the release.

Tests showed that the coatings remain mechanically durable even across grain boundaries and withstand annealing without nanotube breakage.

“There are no physical, chemical, or technical obstacles to adapting our method to the nanostructuring of surfaces made of transition metals other than titanium, such as iron, aluminium, or tantalum. It all depends on the needs,” Chojenka added.

The project was funded by the Polish National Science Centre. Chemical analyses were carried out in cooperation with the Faculty of Chemistry at the Jagiellonian University. (PAP)

PAP - Science in Poland

lt/ bar/