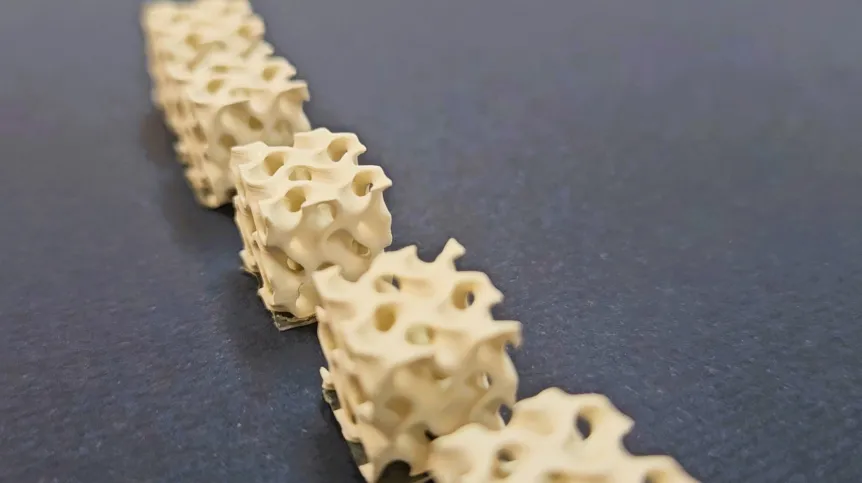

Researchers from the Cracow University of Technology (CUT) and the Polish Academy of Sciences have developed biocompatible, photocurable ceramic resins that mimic bone structures, enabling rapid 3D printing of custom endoprostheses and implants.

The resin allows Digital Light Processing (DLP) 3D printing, which the researchers say ensures precision, high quality, and accurate shape replication.

"Our resin is a true breakthrough," said project leader Klaudia Trembecka-Wójciga, PhD, from the Faculty of Chemical Engineering and Technology of CUT and the Institute of Metallurgy and Materials Engineering of the Polish Academy of Sciences.

"There is no other photocurable, densely ceramic-filled material on the market.This opens new possibilities wherever strength and precision are critical,” she added.

Joanna Ortyl, a professor at CUT, said the project uses zirconia-based bioceramics, known for mechanical strength and wear resistance. "Bone is not homogeneous – it has a complex structure," she said. "We strive to mimic nature, so the implant functions as well as natural bone tissue. 3D printing allows us to design gradient porosity and replicate the internal bone structure."

The method allows implants to be tailored to a patient’s unique anatomy. "We can scan a bone defect and print an implant tailored to a specific patient. This is a major advantage, especially for children or individuals with atypical anatomy," Trembecka-Wójciga said.

The ceramic material is biocompatible, non-toxic, and non-allergenic, reducing the risk of rejection. The researchers also noted that its high friction coefficient ensures it retains properties longer than metallic materials.

"Our technology could benefit patients with degenerative joint diseases, post-traumatic injuries, or bone defects following cancer surgery, all of whom require durable, lightweight, and individually tailored ceramic implants," Trembecka-Wójciga said.

According to CUT, about 60,000 hip replacement procedures are performed in Poland each year, a number that is rising. The demand for high-performance implants is growing.

Latest ceramic hip endoprostheses are highly biotolerant and resistant to abrasion and corrosion, and feature porosity for bone integration. "They are stronger and last longer compared to their metal counterparts. However, their manufacturing process is complicated, which increases production costs and limits their availability," Trembecka-Wójciga said.

The researchers aim for the resin to be compatible with existing DLP printers. "There are excellent printers on the market, but there is a lack of suitable materials. We provide the technology to print biomedical implants without the need to modify the equipment," Ortyl said. "In the future, this solution will allow doctors to print a perfectly fitted implant for each patient, right at the hospital. This is no longer science fiction. It is only a matter of time."

The interdisciplinary team behind the project, titled "Innovative Porous Ceramic Materials Printed Using DLP Technology with High-Performance Photochemical Initiators for Bone Integration," includes scientists from several units, notably the Laboratory of Photochemistry and Optical Spectroscopy led by Ortyl.

The team is preparing a patent application and is in discussions with business partners on commercialization, including licensing and potential start-ups.

This year, the solution won an award in the "Kraków Without Barriers" competition, which recognizes initiatives that facilitate accessibility for people with disabilities.

The project is funded by the Polish National Centre for Research and Development under the 13th edition of the "Lider" program (No. 13/0081/2011). (PAP)

wl/ bar/

tr. RL